Entering Passive, the production revolution of doors and windows quietly takes place here

In today's increasingly competitive door and window industry, production strength is one of the foundations for a brand to establish itself.

Passive Doors and Windows has always been driven by "smart" manufacturing, relying on a modern core production base covering an area of 50000 square meters, redefining doors and windows with advanced technology and strict management, and interpreting brand value with hard core production strength.

Strong scale production strength

The core production base of Passive doors and windows has three major production workshops, covering an area of 50000 square meters. It is a comprehensive intelligent manufacturing center integrating research and development, production, and testing.

After scientific planning and layout, the workshop is divided into multiple functional areas, which operate independently and closely cooperate to form an efficient and orderly production chain. The intelligent and automated production line showcases the magnificent power of modern industry.

High quality products require sound management processes and efficient and flexible manufacturing infrastructure. CRM, ERP, MES and other management systems, together with CNC machining centers, form a solid foundation for optimizing resource allocation, improving production efficiency, and ensuring product quality through management systems.

The production base not only demonstrates the strong strength of Passive, but also provides a solid space guarantee for the large-scale and high-quality production of door and window products, becoming a representative production model in the industry.

Equipment support reaches the level of a millimeter

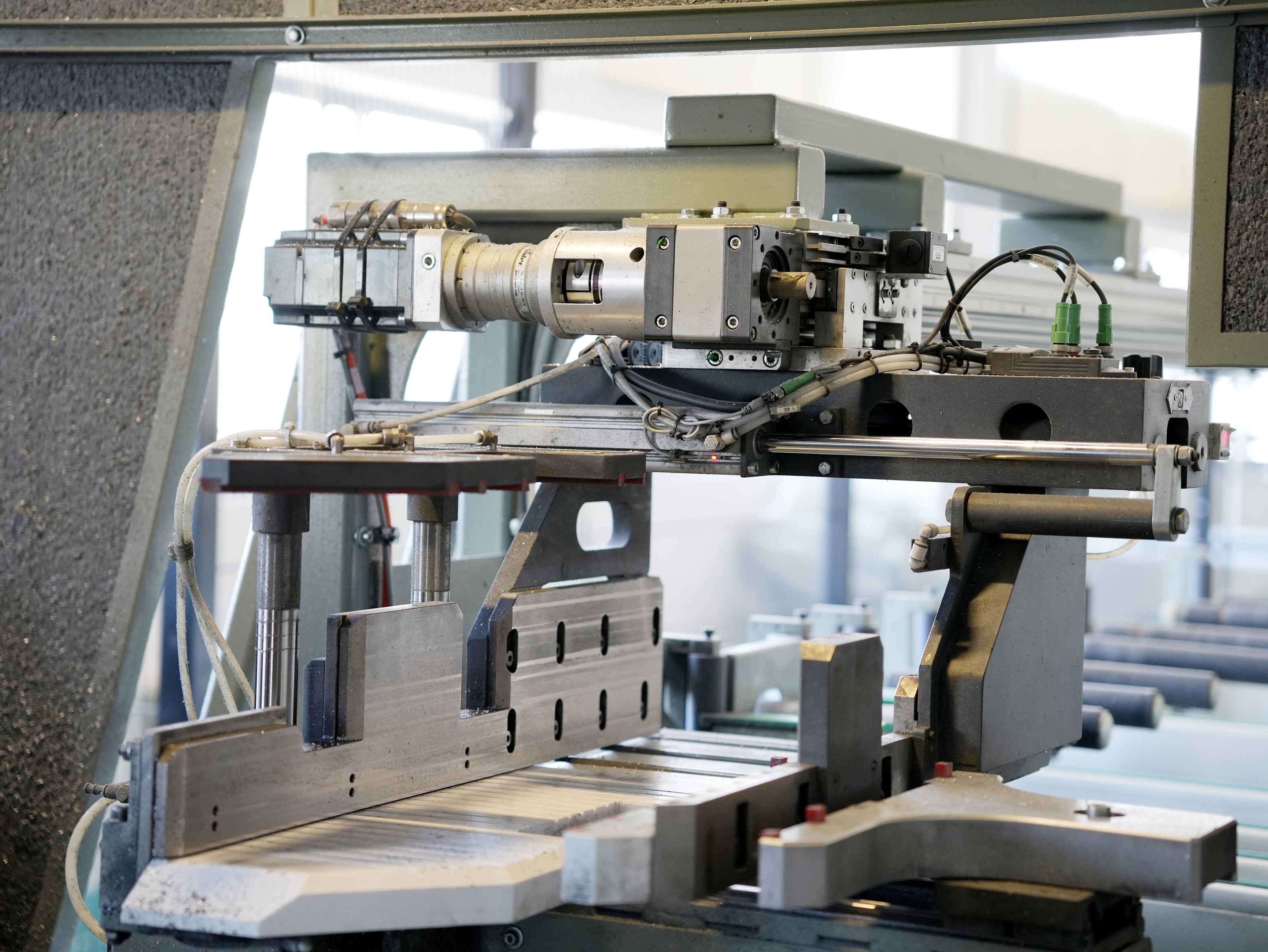

In order to pursue higher product accuracy, Passive Doors and Windows took the lead in importing internationally renowned production equipment.

Passive has introduced four Italian IMG 18 axis machining centers. The CNC positioning system has unparalleled progressiveness in the full-automatic production line. The full-automatic tool system control can carry out high-precision machining on complex spatial surfaces, effectively avoid deviation, make the machining more precise, and make the process more exquisite.

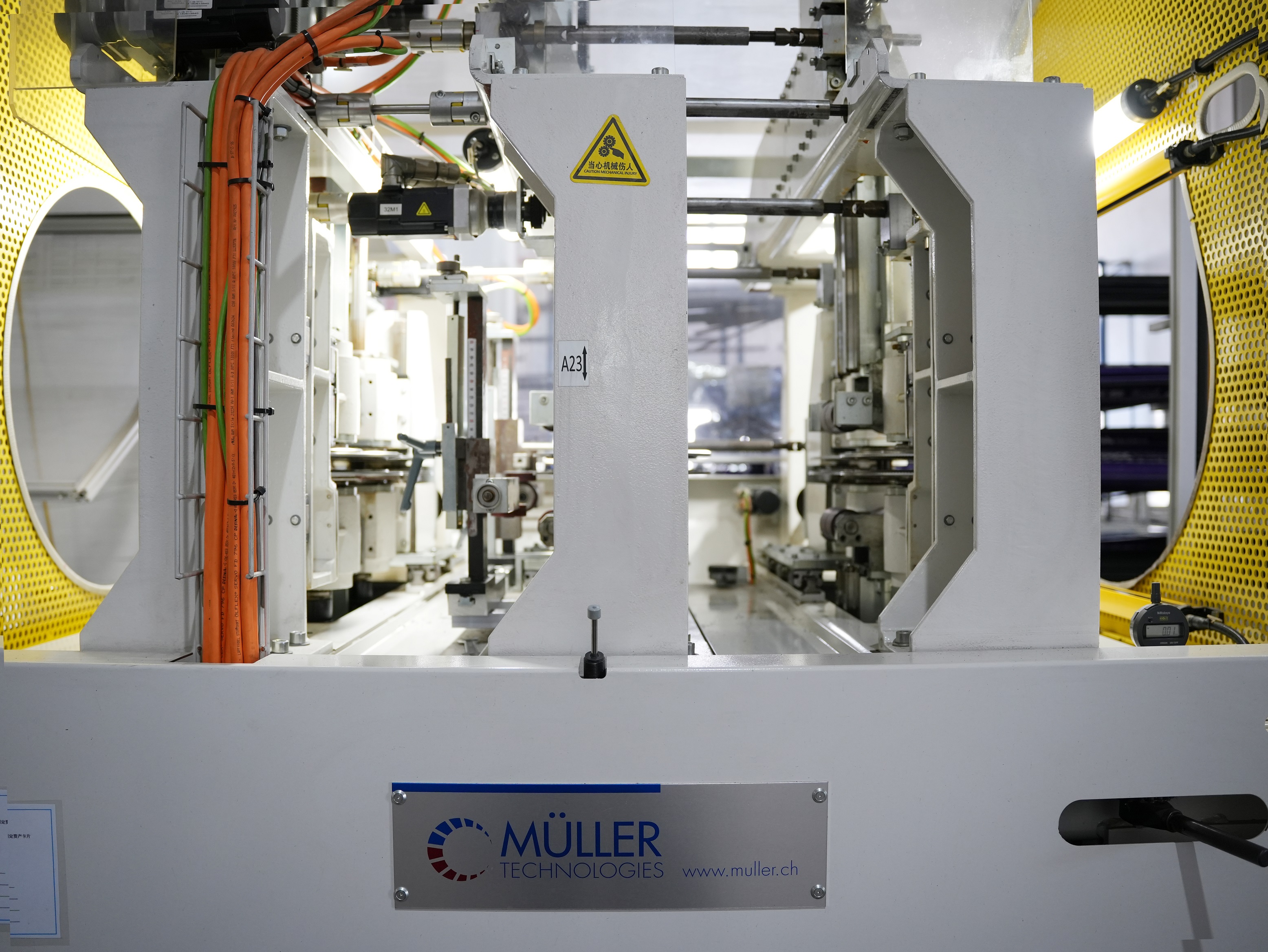

The Swiss Muller fully automatic CNC roller press can input data from nearly a hundred types of Passive profiles into the system, automatically adjust relevant data according to demand, greatly improving work efficiency while achieving higher production accuracy. It can also effectively avoid profile twisting caused by manual adjustment in traditional roller presses.

The use of such imported equipment enables Passive doors and windows to meet or even exceed relevant standards in terms of product accuracy and performance, meticulously crafting every detail to create high-performance and superior quality door and window products for consumers.

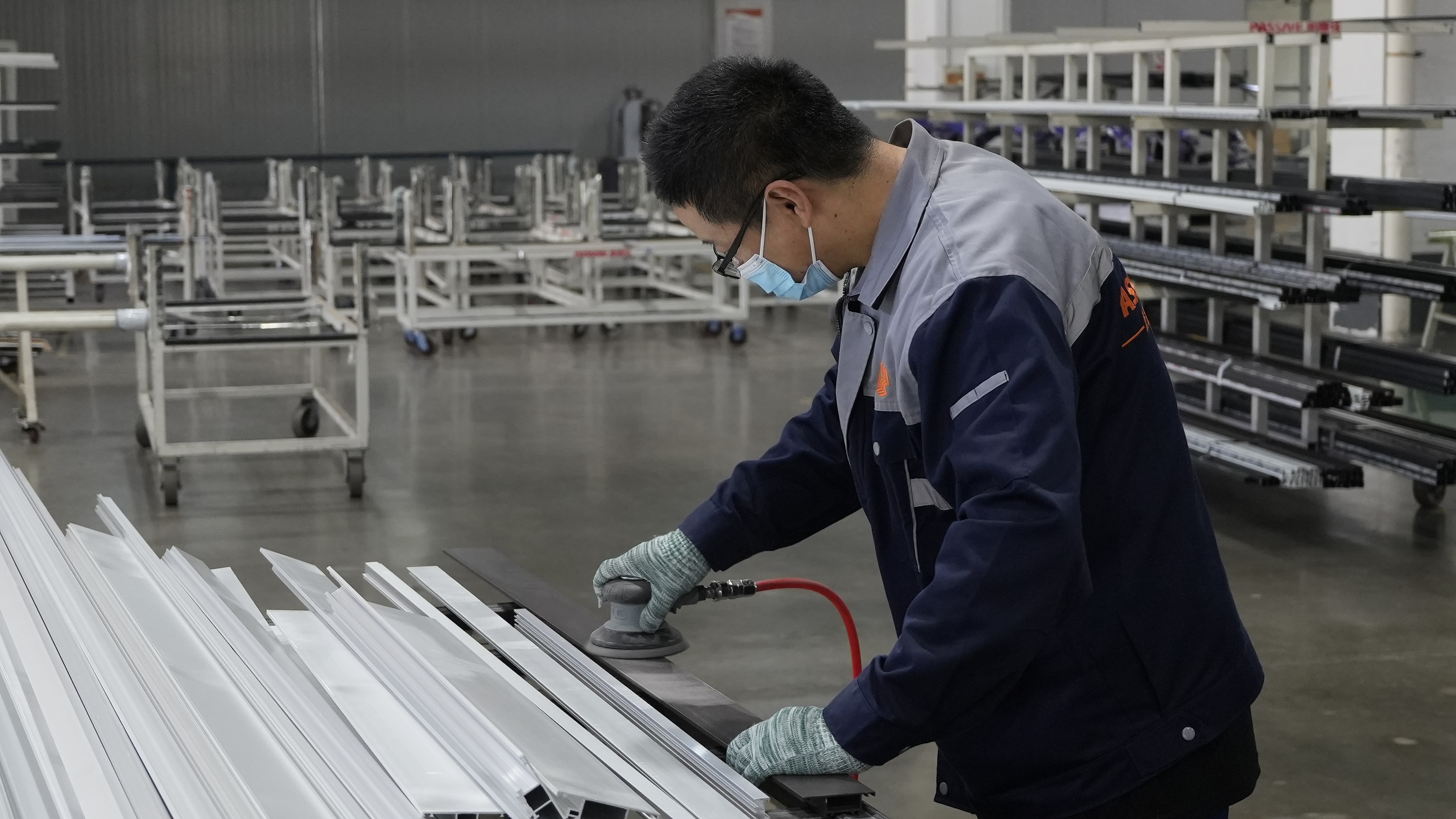

Human machine collaboration escorting quality

Advanced equipment and efficient production lines cannot be separated from scientific management. Passive Doors and Windows has established a comprehensive and rigorous production management system, with strict standards and specifications in every link from raw material procurement to product delivery.

Behind the high-speed operation of the equipment, Passive always values the value of people. The base has gathered multiple professional teams from the front line of production. They are not only proficient in operating machines and manual collaboration, but also rely on rich industry experience to keenly capture optimization space in the production process, empowering the upgrading of door and window quality with technology and craftsmanship.

The combination of machinery and labor not only improves production efficiency, but also enables the brand to quickly respond to market demand and meet diverse customization needs of consumers. It demonstrates Passive's reverence for quality and responsibility towards consumers.

In the future, Passive Doors and Windows will continue to increase research and development investment, optimize production processes, improve management levels, and create safe, comfortable, and beautiful home spaces for consumers with higher quality products and services.