Winter worry free Passive solves the problem of condensation on doors and windows

As the cold wind gradually rises and the temperature drops sharply, the phenomenon of condensation frequently appears in the public eye and becomes the focus of attention. Starting from the underlying logic of condensation, Passive clarifies the ways to deal with different condensation situations and uses advanced technology to protect the dryness of winter.

Analysis of Condensation Principle

In real life, many families will find that fine water droplets quietly condense on the glass of doors and windows, and even flow down the glass, soaking the windowsill and eroding the wall. This phenomenon, known as "condensation," sometimes not only affects the transparency of the home view, but may also pose hidden dangers to the home environment.

The core reason for the occurrence of condensation is the imbalance between temperature and relative humidity. From a physical principle perspective, the amount of water vapor that can be contained in the air decreases with decreasing temperature. When the water vapor in the air reaches saturation, if the ambient temperature continues to drop, excess water vapor will transform from a gaseous state to liquid water and precipitate, adhering to the surface of objects at lower temperatures. This phenomenon is called "condensation", and the critical temperature at which this phenomenon occurs is the "dew point temperature" (abbreviated as "dew point").

The causes and response methods of condensation in different locations are completely different. After clarifying the principle of condensation, it can be deduced that not all condensation on doors and windows is a signal of a problem. The key is to prescribe the right medicine.

Indoor side condensation on doors and windows: a natural phenomenon that requires no anxiety

If condensation only occurs on the inner surface of doors and windows, and is mostly concentrated in indoor scenes such as cooking and bathing, or during periods of low outdoor temperature, this is generally a normal natural phenomenon and there is no need for excessive anxiety.

As the main carrier of indoor and outdoor heat exchange, doors and windows have glass and profile surfaces that are easily affected by low outdoor temperatures, leading to a decrease in temperature. Starting from the underlying logic, the cause of this condensation is the presence of sufficient water vapor indoors (i.e. high relative humidity), as well as a large temperature difference between indoors and outdoors, resulting in the temperature on the side of the glass room being lower than the dew point temperature of the indoor air.

To address this type of condensation, the following methods can be used to optimize and alleviate it: firstly, controlling indoor humidity reasonably to reduce the source of water vapor, such as turning on the range hood in a timely manner when cooking, turning on the exhaust fan when taking a shower, and using dehumidification equipment to avoid the accumulation of a large amount of water vapor; The second is to strengthen ventilation and air exchange, maintain air circulation, and balance indoor and outdoor temperature and humidity; The third is to choose system doors and windows with better comprehensive performance, by improving the thermal insulation capacity of doors and windows, reducing the difference between the temperature of the glass indoor side and the indoor air temperature, and fundamentally reducing the possibility of condensation.

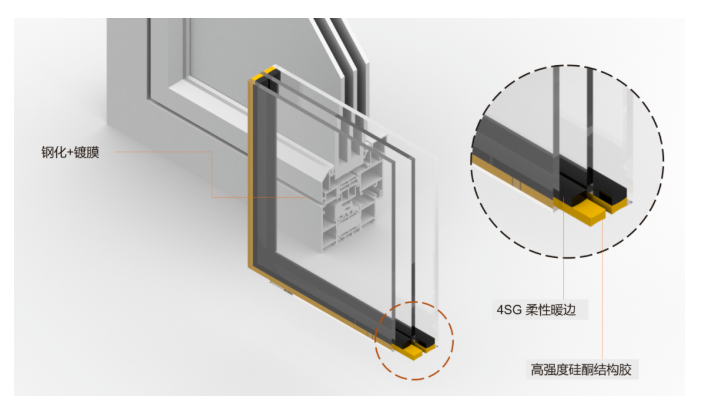

Passive uses a systematic combination of profiles, insulation strips, glass, and adhesive strips, with polyurethane foam sealing at the joints and silicone sealant, to reduce air convection, heat loss, and dew formation at the joints, and to minimize the phenomenon of water vapor channels.

In terms of glass configuration, Passive doors and windows can use 4SG glass. 4SG is a thermoplastic reactive spacer sealant with low thermal conductivity. It can reduce the heat conduction at the glass edge, thereby reducing the heat loss at the glass edge. It can increase the K value of insulating glass by about 0.1, effectively reducing the probability of condensation on door and window frames and glass edges, and inhibiting the production of mold.

Condensation inside the glass hollow layer: sealing failure urgently needs to be addressed

If condensation occurs inside the hollow layer of the glass rather than on the surface, it is necessary to be highly vigilant, as this is a clear signal of the failure of the sealing performance of doors and windows.

Qualified insulating glass will be filled with gas between two layers of glass and sealed with professional sealing measures to isolate external water vapor, ensuring that the interior of the insulating layer is dry. Once condensation or fogging occurs within the hollow layer, it indicates that the sealing structure has been damaged and the performance of the glass has significantly deteriorated. If not repaired or replaced in a timely manner, the long-term accumulation of water vapor will directly affect the service life of doors and windows.

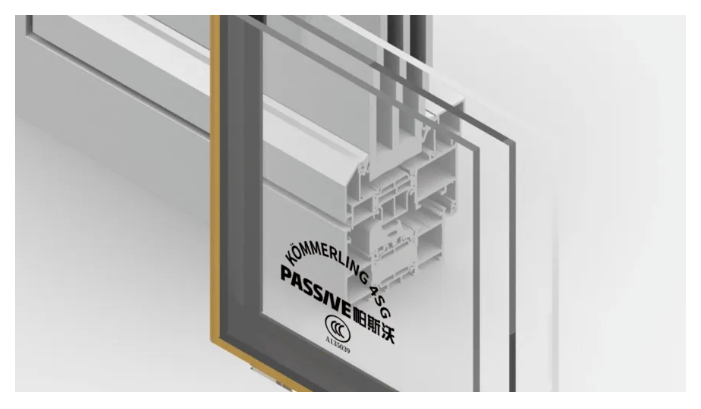

From this, it can be seen that paying attention to the sealing quality of glass edges and choosing insulated glass with longer sealing performance is the key to avoiding such problems. Passive chooses and uses mature and stable 4SG glass. The K ö dispace 4SG system not only reduces natural condensation due to its low thermal conductivity, but also provides long-lasting and high-quality sealing for the insulating glass itself.

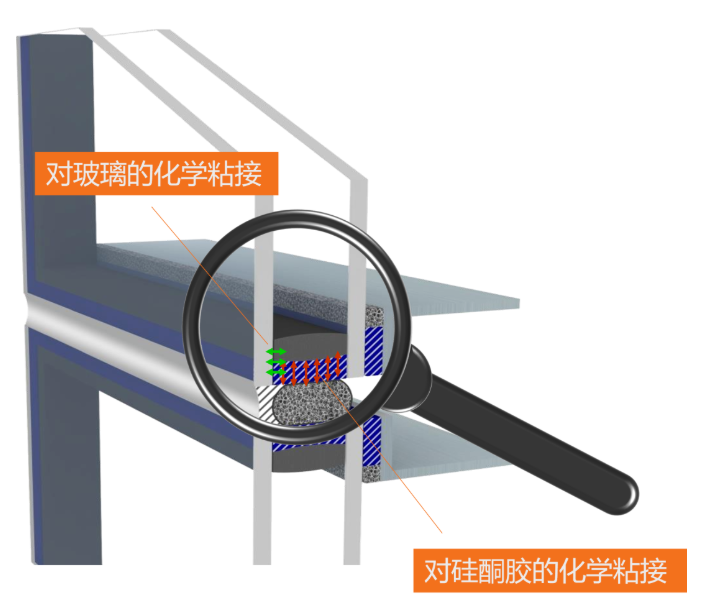

The K ö dispace 4SG system uses integrated elastic sealing materials, which are flexible glass spacer strips composed of integrated desiccants, butyl rubber, and molecular sieves. The flexible characteristics prevent the joints from becoming weak sealing points, and can maintain long-term reliable sealing while meeting the needs of different glass shapes. In addition, high and low temperature resistant and anti-aging high-quality sealing materials can adapt to extreme environments and are not easy to age and crack after long-term use. At the same time, the 4SG system can achieve true chemical bonding with glass and secondary sealant, and maintain uniform stress distribution during the pumping process of the hollow glass cavity, forming a structural seal and ensuring the long-term service life of the hollow glass.

Winter condensation on doors and windows may seem like a minor issue, but it is actually related to home comfort and living environment safety. Passive Doors and Windows provides professional high-end door and window solutions to safeguard users' dryness and warmth every winter, ensuring comfort and peace of mind are always with them.