Passive adds sawing and milling production line to build intelligent equipment matrix for doors and windows

Intelligence initiates a new journey, and precision builds human habitation. At the beginning of 2026, Passive introduced the Red CNC intelligent laser sawing and milling production line, combining with existing advanced production equipment such as the Italian Yimeiji 18-axis machining center and the Swiss Müller fully automatic CNC roller press, to build a more competitive new generation of intelligent equipment matrix for doors and windows.

Equipment introduction, deep cultivation in high-end manufacturing

Passive has added a new intelligent laser sawing and milling production line, which integrates laser technology, intelligent control, and precision machining, reshaping the production precision and processing efficiency of doors and windows.

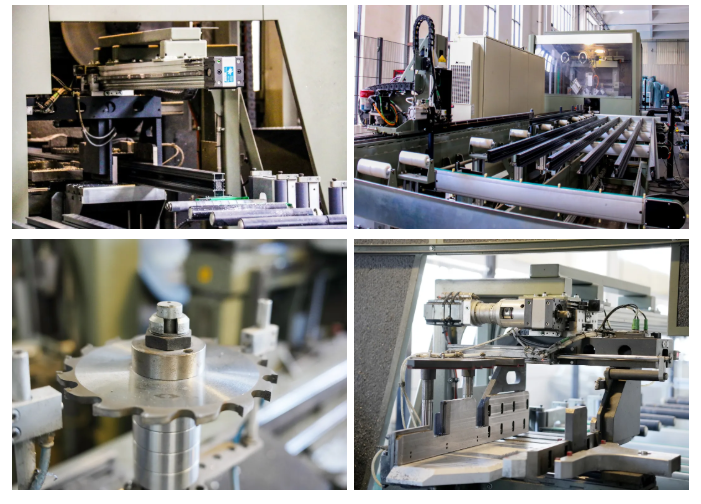

Traditional sawing and milling processes are susceptible to factors such as mechanical wear and manual operational errors, making it difficult to meet the stringent precision requirements of high-end doors and windows. Passive has added a sawing and milling production line that utilizes laser drilling and marking, multi-spindle coordinated milling, and fixed-angle three-blade cutting for high efficiency and stability. The processing accuracy can reach the micrometer level, enabling precise control over both multi-angle profile cutting and milling of complex irregular structures. This level of precision ensures tighter splicing of door and window profiles, effectively enhancing the performance of doors and windows, and guaranteeing the stability and reliability of Passive's product quality from the source.

The newly added intelligent laser sawing and milling production line at Passive is equipped with an intelligent control system. From order ERP software to seamlessly linked MES system, and to data flow at the equipment level, it achieves automated operation throughout the entire cutting and milling process, significantly reducing manual intervention. Compared to traditional production lines, its production efficiency has been greatly improved, enabling rapid response to multiple batches and small-batch custom orders, ensuring the continuity and efficiency of production processes.

Matrix collaboration empowers the future of human habitation

The introduction of this new equipment is not merely an isolated technological addition, but rather a deep synergy with existing equipment, building a more powerful and comprehensive production equipment matrix for Passive.

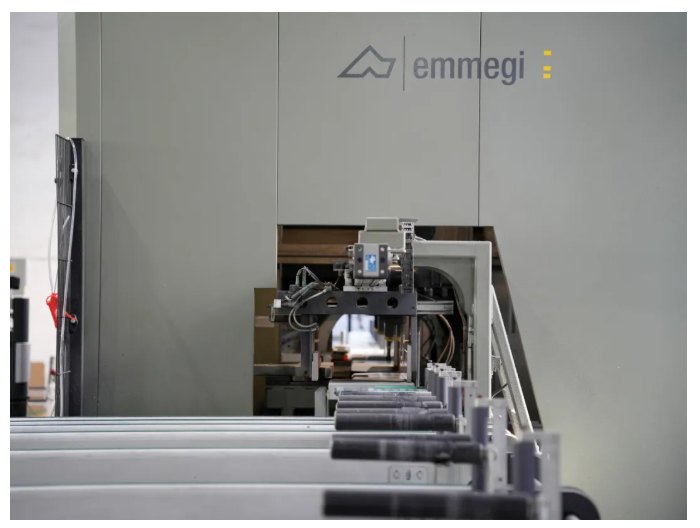

Passive has successively introduced four Italian Yimeiji 18-axis machining centers. Its CNC positioning system exhibits unparalleled progressiveness on the fully automated production line, capable of cutting and milling various door and window profiles with micron-level precision. The fully automated tool system control allows for high-precision machining of complex spatial surfaces, effectively avoiding deviations, making the processing more precise and the craftsmanship more exquisite.

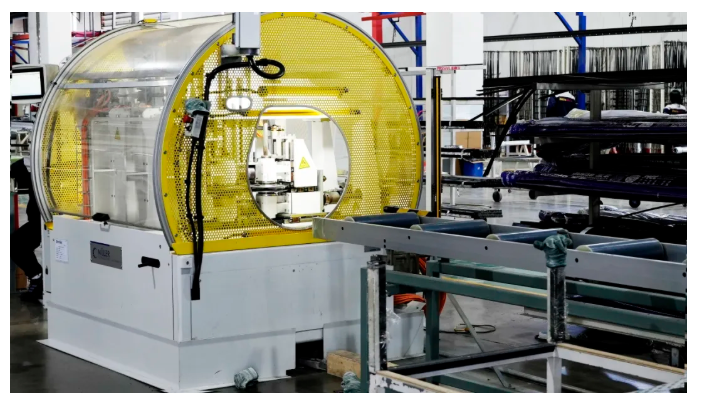

The use of the Müller fully automatic CNC roller press in Switzerland serves as a solid backbone for the production of high-quality doors and windows. It can input data from nearly a hundred profiles of Passive into the system, automatically adjust according to demand, and quickly and accurately complete the assembly of different components, while effectively avoiding the twisting of profiles caused by manual adjustment in traditional roller presses.

The introduction of a new intelligent laser sawing and milling production line, coupled with the further enhancement of the production equipment matrix, not only signifies a leap in Passive's production capabilities, but also redefines the high-end manufacturing standards for doors and windows.

Passive doors and windows utilize intelligent production to streamline every step from processing to assembly, ensuring that every door and window embodies the dual strength of craftsmanship and technology.