Passive's Independent Research and Development and Testing Center Drives the New Journey of Door and Window Technology Iteration

In the current era of rapid industry development, not all door and window factories possess the solid backing of professional R&D laboratories and performance testing centers to support high-quality products. While some brands still rely on external testing and remain stagnant in conventional production, Passive has completed platform construction and talent supplementation, achieving full-chain independent control from R&D to output.

R&D testing is not a standard configuration for door and window factories

According to industry standards, door and window products must pass rigorous tests on multiple core indicators such as air tightness, water tightness, wind pressure resistance, thermal insulation, and sound insulation to ensure stable performance under different climatic environments and usage scenarios.

However, due to the substantial capital investment required for site construction, professional equipment procurement, talent team allocation, continuous operation, and maintenance, some door and window factories fail to give due attention to this crucial aspect.

Some door and window factories rely on the testing data provided by upstream material suppliers, ignoring the differences in overall performance after material combination. Some enterprises only entrust third-party organizations to conduct spot checks before product launch, which is difficult to cover the quality fluctuations throughout the entire production cycle. What's worse, some even skip the testing process altogether, relying on empirical judgment instead of scientific verification, resulting in inconsistent product performance and causing many troubles for consumers, such as air leaks, water infiltration, poor sound insulation, and potential safety hazards.

Brands that truly possess independent research and development laboratories and comprehensive performance testing centers are rare in the industry, and this is precisely where Passive stands apart from ordinary factories.

Build our own platform and embark on the path of high-quality development

The self-built R&D laboratory and performance testing center of Passive is not a gimmick for industry competition, but a strategic choice for the brand to base its long-term development on, and it is also a tangible manifestation of responsibility towards users.

From an industry perspective, on one hand, there is a large-scale production transformation from traditional manufacturing to technological and intelligent manufacturing. On the other hand, consumers' demand for doors and windows has evolved from basic shelter and protection from the wind and rain to comprehensive needs such as energy saving and consumption reduction, intelligence and convenience, health and comfort. Relying on external testing or production based solely on experience cannot accurately capture changes in market demand, making it even more difficult to achieve technological breakthroughs and innovations. Only by establishing an independent research and development testing system can we grasp the technological discourse power, promote product iteration and upgrading, and boost high-quality development of the industry.

From the perspective of the end-user, doors and windows, as large durable goods in home decoration, have a direct impact on the living experience and quality of life for decades. Passive has established its own research and development laboratory and performance testing center, essentially aiming to prioritize quality control. Each link undergoes scientific experiments and precise testing to ensure that every product meets or even exceeds relevant standards, allowing consumers to enjoy stable, reliable, and high-quality door and window products. This full-chain quality control cannot be achieved solely through external testing, and it is Passive's solemn commitment to consumers.

Deeply implement and compose a new chapter with full-dimensional advantages

Passive's R&D laboratory and performance testing center is a comprehensive scientific research platform integrating R&D innovation, performance verification, process optimization, and standard setting, providing comprehensive support for product quality improvement and technological breakthroughs.

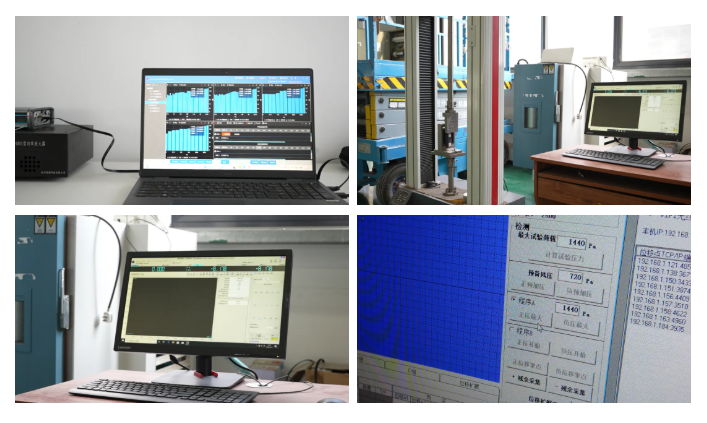

Passive Lab is equipped with advanced material analysis equipment, simulation computing systems, etc., focusing on research in the fields of door and window profile structure, sealing technology, thermal insulation, intelligent control, energy conservation, and environmental protection. For example, in response to climatic differences in different regions, Passive's R&D team has designed customized door and window solutions that are suitable for different regions by simulating extreme weather conditions such as heavy rain, high temperatures, and severe cold. These solutions ensure that the products maintain excellent thermal insulation performance in the severe cold of the north and possess strong wind pressure resistance in typhoon weather in the south.

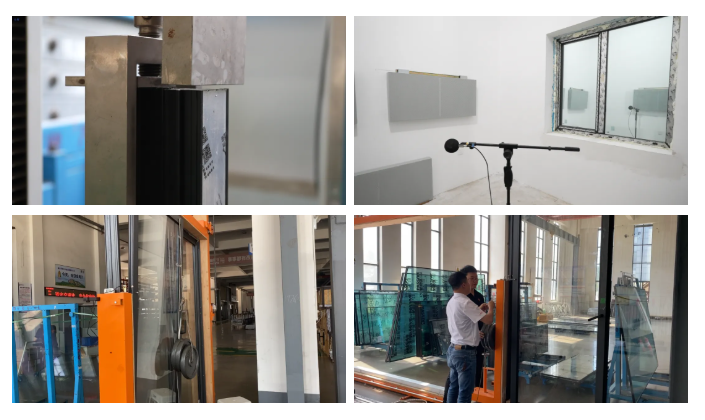

The Passive Testing Center strictly adheres to industry standards and has established a comprehensive performance testing platform. Here, every product undergoes rigorous "extreme" testing: in airtight performance testing, precise measurements of air infiltration are taken to ensure the tightness of doors and windows; in waterproof performance testing, rainstorm-level water pressure impacts are simulated to verify the waterproof capability of doors and windows; in wind pressure resistance testing, structural stability of doors and windows under strong wind conditions is tested through gradual pressure increases; in addition, there are sound insulation performance testing, thermal insulation performance testing, repeated opening and closing durability testing, and many other testing items, comprehensively covering the full range of product usage scenarios.

The Passive R&D Laboratory and Performance Testing Center accurately identifies process shortcomings through the detection and analysis of various data during the production process, driving the iterative upgrading of production processes. Meanwhile, relying on continuous scientific research accumulation and testing data, Passive actively participates in the discussion and formulation of industry standards, striving to transform its own technical experience into norms that the industry follows collectively, and promoting the quality upgrade of the entire industry.

From the conception of independent research and development testing to the implementation of a complete system, Passive has demonstrated its determination and perseverance in a long-term battle, speaking through achievements, truly presenting the temperature of scientific research and quality commitment to users, and redefining the standards that high-end doors and windows should have with the power of independent innovation.

Passive firmly believes that a truly high-end door and window brand will ultimately rely on quality to establish its foundation and innovation to achieve long-term success.